Provide Copeland compressor replacement parts, like terminal plates, oil crankcase heaters, electrical feed-throughs, gasket sets, valve plate kits, connecting rod and piston, crankshafts, bearing bushes, thrust washers, wrist pins, piston rings, suction valve slices, discharge valve slices, Oil splashers, Shutoff valves, plastic rings for piston pins, circlip, oil pump, valve plate reeds, filters, absorb springs, junction boxes.

Copeland compressors are widely popular among users due to their stable performance. The choice and quality of their accessories directly impact the compressor’s lifespan and performance. Below are the common accessories for Copeland compressors and detailed purchasing recommendations:

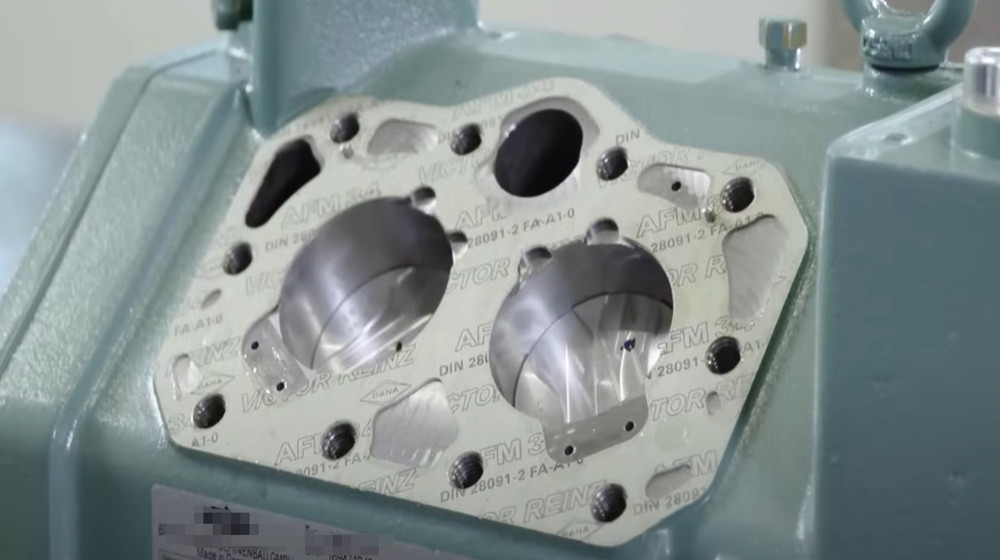

Function: The valve plate of the Copeland compressor controls the intake and discharge of gas and is one of the core components of the compressor.

Purchasing Recommendation: Ensure compatibility with the compressor model; prioritize Copeland compressor valve plates made of heat-resistant and corrosion-resistant materials, such as stainless steel or composite materials.

Function: The Copeland piston and connecting rod of the Copeland compressor drive gas compression and are key components in converting mechanical energy into gas pressure.

Purchasing Recommendation: Ensure the material is wear-resistant and has an appropriate weight, such as aluminum alloy or special steel; check machining accuracy to avoid abnormal vibrations caused by dimensional errors.

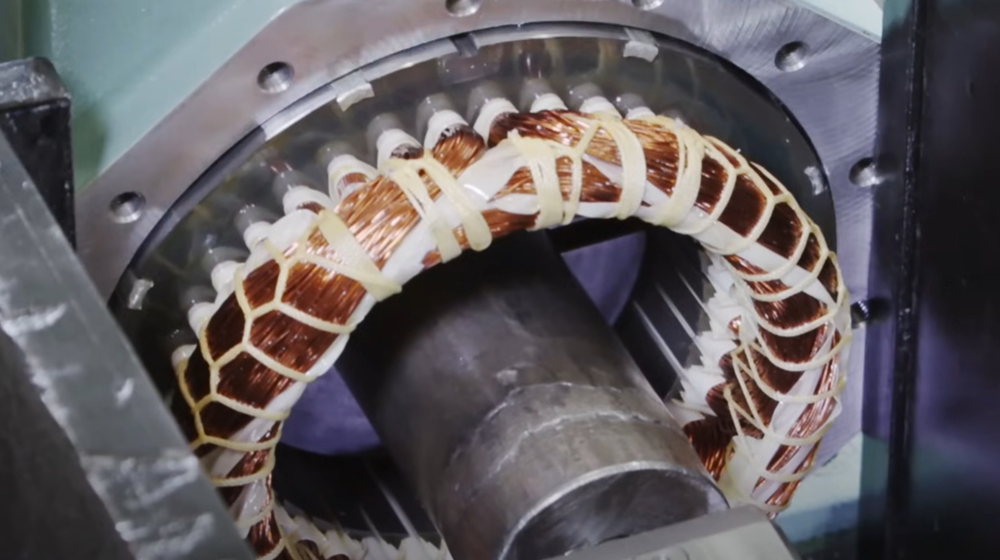

Function: The motor coil of the Copeland compressor provides the power source for the compressor’s operation.

Purchasing Recommendation: Choose high-efficiency copper coils to ensure excellent electrical conductivity and thermal stability; verify that the power specifications match the original motor.

Function: The Copeland sealing gasket prevents refrigerant or lubricant oil leakage, ensuring the compressor’s airtightness.

Purchasing Recommendation: Select materials compatible with the refrigerant type (such as R22 or R410A), commonly nitrile rubber or fluorine rubber; pay attention to the temperature resistance and corrosion resistance of the seal.

Function: The Copeland oil filter and screen in the Copeland compressor filter out impurities from the refrigerant, protecting internal components from contamination.

Purchasing Recommendation: Verify that the mesh size is suitable for the compressor’s operating pressure; prefer OEM or high-quality alternatives to avoid insufficient filtration and potential malfunctions.

Function: The suction and discharge valves control the flow direction of the refrigerant, ensuring efficient compression.

Purchasing Recommendation: Check the valve plate material and select durable materials (such as spring steel); ensure the valve design matches the original unit to avoid sealing issues that could reduce efficiency.

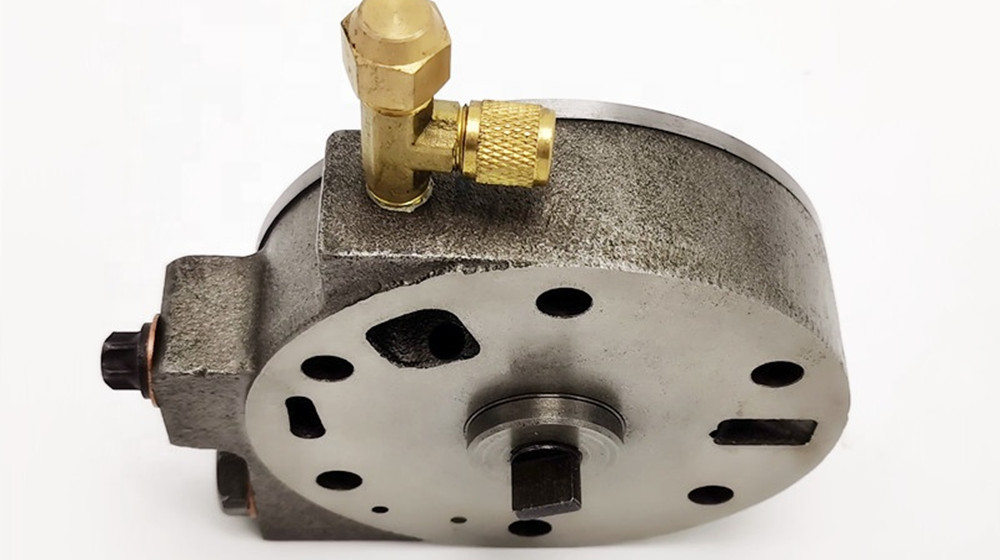

Function: The Copeland oil pump provides lubrication to the compressor, reducing wear on parts.

Purchasing Recommendation: Choose an Copeland compressor oil pump compatible with the original compressor oil; ensure the pump casing has good pressure resistance and wear resistance.

Function: The Copeland crankshaft connects the motor and piston, transmitting power.

Purchasing Recommendation: Prefer Copeland compressor crankshafts made from high-strength steel; ensure machining accuracy to guarantee balance and durability.

Due to the high efficiency and stability of Copeland compressors, they are widely used in refrigeration and air conditioning applications. However, during operation, Copeland compressor accessories may suffer damage due to wear, improper operation, or insufficient maintenance. Below are some common accessory issues and professional solutions:

Problem: Damage to the valve plate reduces compression efficiency, weakening cooling performance; abnormal noise during compressor operation.

Solution: Regularly check the valve plate for wear or cracks and replace it if necessary; use OEM or high-quality alternatives that are heat-resistant and deform-resistant; ensure proper installation and tightening to avoid leakage issues.

Problem: Wear of the piston and connecting rod increases compressor vibration, raises noise levels, and causes abnormal lubricant consumption.

Solution: Regularly check lubricant quality and levels to maintain proper lubrication; replace the piston and connecting rod assembly with high-quality, precisely machined parts; check the cylinder liner for wear and replace related components if needed.

Problem: The Copeland compressor cannot start or frequently trips; the motor temperature rises abnormally.

Solution: Check the power supply voltage to ensure it is stable and avoid overload operation; ensure the cooling system is functioning properly to prevent motor overheating; replace the motor coil with a heat-resistant, well-insulated OEM part.

Problem: Refrigerant or lubricant oil leaks, causing a decrease in cooling performance; system pressure instability and reduced efficiency.

Solution: Regularly replace seals and choose corrosion-resistant materials suitable for the refrigerant (such as fluorine rubber); apply an appropriate amount of lubricant when installing the seals to ensure proper placement without distortion.

Problem: Restricted refrigerant flow causes compressor overheating or reduced performance; increased wear on internal components.

Solution: Regularly clean or replace the filter and oil filter to prevent debris accumulation; use high-quality refrigerants and lubricants to minimize contamination; check the refrigerant system for sources of contamination and clean promptly.

Problem: Reduced compressor efficiency and increased load; abnormal noise or refrigerant leakage.

Solution: Check for wear on the valve plates and springs, replacing them if necessary; ensure the valve seats are clean and free of foreign objects; adjust the valve installation to ensure a proper seal.

Problem: Insufficient lubrication, severe component wear, oil pressure alarm, or abnormal oil levels.

Solution: Regularly check the oil pump pressure to ensure normal operation; use the recommended oil type and keep it clean; replace oil pump components with high wear resistance and those compatible with the original.

Problem: A fractured or deformed crankshaft prevents the compressor from starting or causes irregular vibration; internal components may collide and generate noise.

Solution: Check the alignment between the motor and crankshaft to avoid installation issues that could cause fractures; replace the crankshaft with one made from high-strength materials; regularly maintain the lubrication system to reduce friction between components.

Complete Guide to One-Stop Procurement of Copeland Semi-Hermetic Compressor Repair, Rebuild, Remanufacturing and Refurbishment Replacement Parts, saving your time and cost in your purchasing process.

We are a professional manufacturer of Copeland compressor parts. Feel free to contact us! We are dedicated to serving you 24/7!

MEDINO has been a leading manufacturer in refrigeration compressor parts field for 10+ years. With experience in electric terminal plates and oil crankcase heaters producing, we can provide high-quality terminal plates and all compressor parts to improve your compressor performance.

You can get a price of this model or send us any question to get any information you would like to know, we will reply to you soonest.