Our factory specializes in the design and production of Bitzer Crankcase Heater. We use durable and heat-resistant materials to ensure the high quality and reliability of the crankcase heaters, allowing them to function properly even in harsh environments.

Energy-efficient design is one of our strengths, enabling the crankcase heaters to consume minimal power while providing optimal protection for semi-hermetic compressors.

We supply Bitzer crankcase heater to the global market for various applications, including commercial, industrial, and residential refrigeration and air conditioning systems.

The primary purpose of the Bitzer crankcase heater is to prevent refrigerant migration and oil dilution in refrigeration and HVAC systems, especially when the compressor is not in operation.

When the compressor is shut off, especially in cold environments, refrigerant can condense and migrate into the crankcase. By warming the oil inside the compressor, the Bitzer crankcase heater prevents the refrigerant from condensing in the crankcase.

If refrigerant mixes with the oil in the crankcase, it will dilute the oil and reduce its lubricating properties. This can lead to insufficient lubrication when the compressor starts, potentially causing wear on the Bitzer compressor components.

By maintaining a stable oil temperature and preventing refrigerant migration, the Bitzer crankcase heater helps reduce component wear during compressor startup. This extends the lifespan of the Bitzer compressor and reduces the need for regular maintenance.

The Bitzer crankcase heater ensures that the oil inside the compressor is at the proper temperature when the system starts up, preventing liquid refrigerant from entering the compressor and causing damage.

The voltage size and power rating of the Bitzer crankcase heater may vary depending on the compressor model, as well as specific applications and requirements. We can also customize heaters based on your needs. Below are some standard Bitzer crankcase heaters:

The Bitzer crankcase heater typically come in 110 to 120 volts and 220 to 240 volts, but the specific voltage is customized based on the voltage requirements of different countries and the compressor models of various brands.

The standard power rating of Bitzer crankcase heater ranges from 50W to 300W, with common ratings of 140W, 160W, 180W, 220W, 280W, and 300W. Of course, you can also customize a higher power rating based on the specific operational requirements and working conditions of the semi-hermetic compressor.

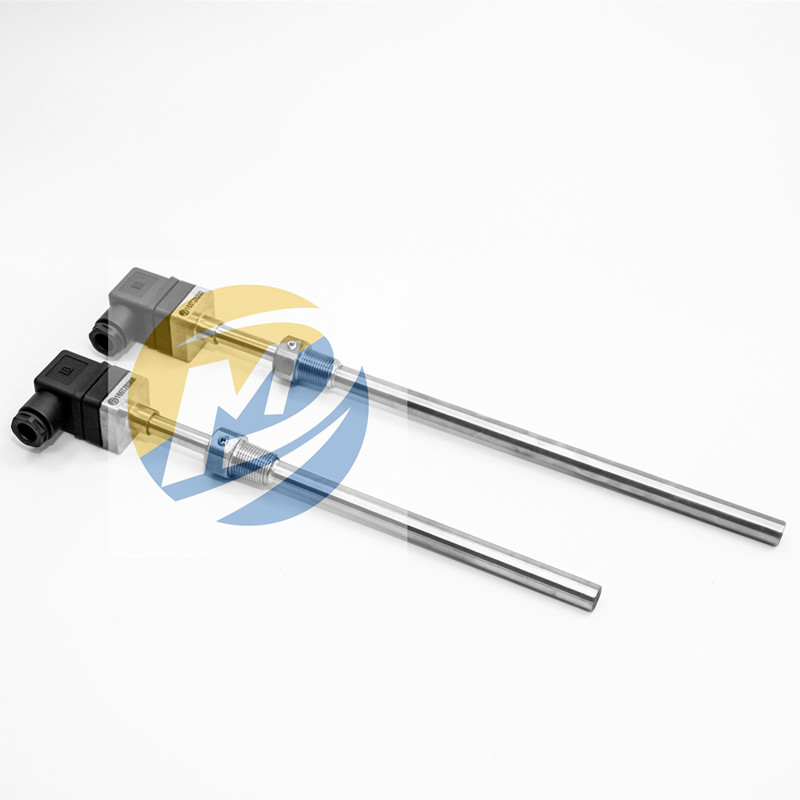

The size of the Bitzer crankcase heater primarily includes the diameter and length of the heating tube, as well as the thread of the mounting hole. When purchasing replacement heaters, it is essential to choose based on the original size and specifications.

The standard diameter of Bitzer crankcase heaters is usually 10 mm or 12 mm, and the standard lengths are generally 180 cm, 225 cm, and 295 cm.

If you want to know the exact voltage, size, and power rating of the Bitzer crankcase heater, it’s best to consult Bitzer technical documents or product labels, as this information will be very useful when you’re looking to purchase a replacement Bitzer crankcase heater.

Are you looking to buy a replacement Bitzer crankcase heater? Perhaps you are searching for one…

We are a professional manufacturer of Bitzer compressor parts and Bitzer crankcase heaters for you.

Getting OEM parts of Bitzer Compressors like Crankcase heaters from us. We have been an original manufacturer for many years in the market. Reliable quality and best management to ensure your business goes well and firm! We have almost all types of models and parts for you always. Contact Right Now!

We will get back to you with fastest responsibility if you have any question of the Bitzer Crankcase Heater

MEDINO has been a leading manufacturer in refrigeration compressor parts field for 10+ years. With experience in electric terminal plates and oil crankcase heaters producing, we can provide high-quality terminal plates and all compressor parts to improve your compressor performance.

You can get a price of this model or send us any question to get any information you would like to know, we will reply to you soonest.