When it comes to compressors, not all rebuilds are created equal. While many people use the terms rebuilt and remanufactured interchangeably, there’s a big difference—and it matters to performance, reliability, and long-term value.

A rebuilt compressor is typically repaired just enough to get it working again. Only visibly damaged or completely failed parts are replaced. If a component is still functioning—even if it’s on the verge of failure—it’s usually left in place.

This approach may get your system running in the short term, but it comes with risk. Aging parts and inconsistent rebuild practices can lead to early failures and costly downtime.

Built to OEM Standards:

A remanufactured compressor is more than a repair—it’s a full restoration. Each unit is rebuilt from the ground up to match the latest OEM specifications.

That means: All components, including those that are still functional but outdated, are replaced or upgraded. The unit is fully disassembled, cleaned, inspected, and tested. Every compressor meets UL certification and OEM performance standards.

In short, you’re getting performance that’s as close as possible to a brand-new unit—backed by warranty and quality assurance.

If you want performance you can trust, a warranty you can count on, and fewer issues down the road, remanufactured compressors are the smart choice.

Rebuilt compressors may contain a mix of new, used, and worn parts. Some rebuilders even use one gasket type across all units, ignoring specific model requirements.

Remanufactured compressors, like Copeland Certified units, go through a meticulous rebuild process. Valve plate gaskets are matched to piston height, over 500 parts are inspected or replaced, and every component is tested to deliver factory-level performance.

As a contractor or service provider, your reputation depends on the quality of the products you install. Customers expect lasting solutions—not quick fixes.

Choosing a remanufactured, OEM-certified compressor shows your clients that you stand for quality, safety, and long-term value. Fewer callbacks. Happier customers. Stronger brand image.

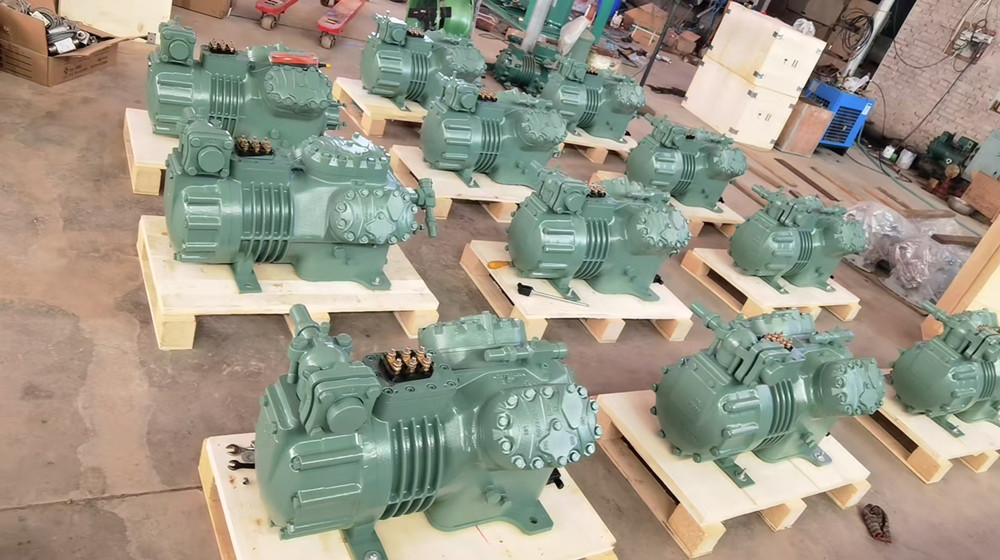

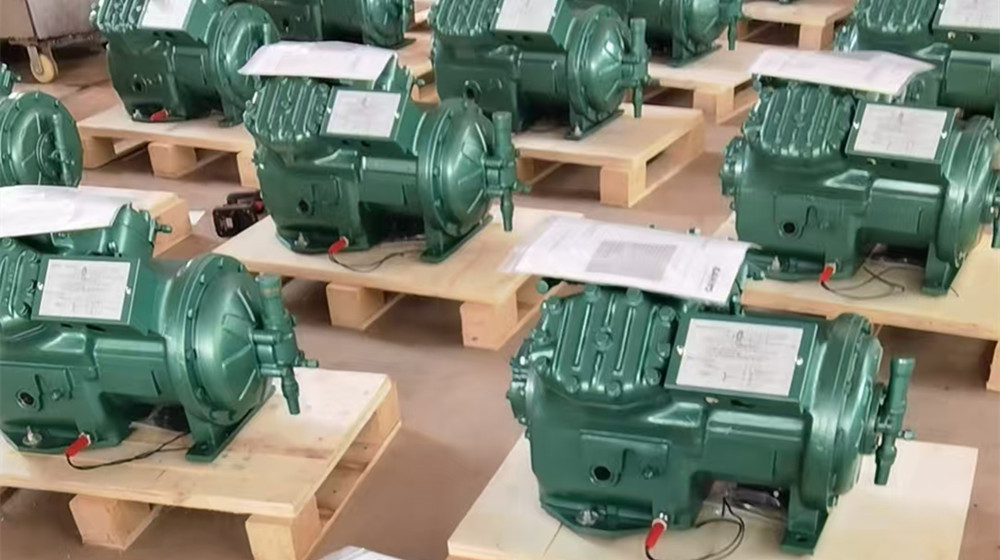

Here’s how every Bitzer Certified remanufactured compressor is rebuilt:

Teardown: Units are fully disassembled. All critical components (valves, bearings, connecting rod & piston, valve plates, seals) are removed and evaluated. Cleaning: Every part is cleaned to remove residue, oil, and contaminants. Qualification: Each component is tested. Parts that don’t meet engineering specs are replaced with new or requalified alternatives.

Assembly: Technicians follow strict, guided processes to avoid errors. If the wrong part is selected, the system automatically halts the build. Repainting: Units are painted for consistent appearance and corrosion protection. Inspection: Each compressor is fully tested for electrical and mechanical performance before packaging.

MEDINO has been a leading manufacturer in refrigeration compressor parts field for 10+ years. With experience in electric terminal plates and oil crankcase heaters producing, we can provide high-quality terminal plates and all compressor parts to improve your compressor performance.

You can get a price of this model or send us any question to get any information you would like to know, we will reply to you soonest.