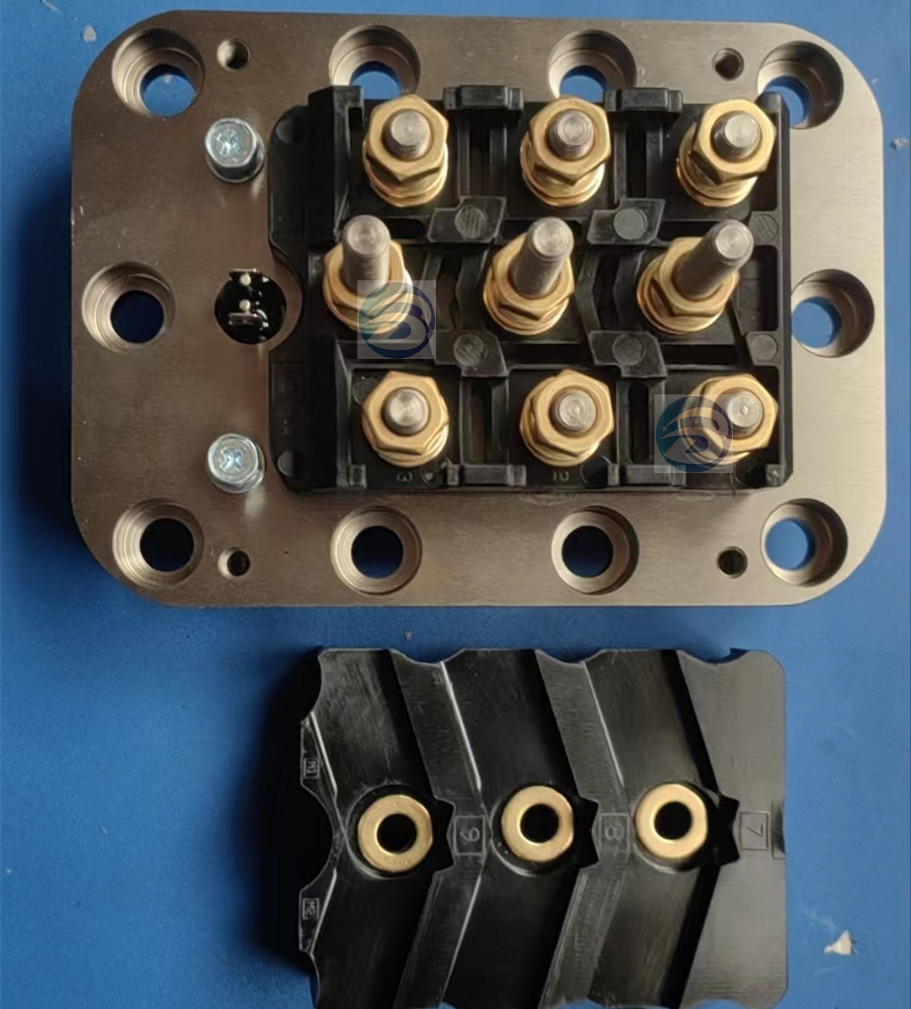

We are a factory specializing in the production of Bitzer compressor accessories, focusing on the research, development, manufacturing, and sales of Bitzer terminal plates. We strictly adhere to original factory standards to ensure that each product meets industry-high standards in dimensions, materials, and performance, catering to the needs of customers worldwide.

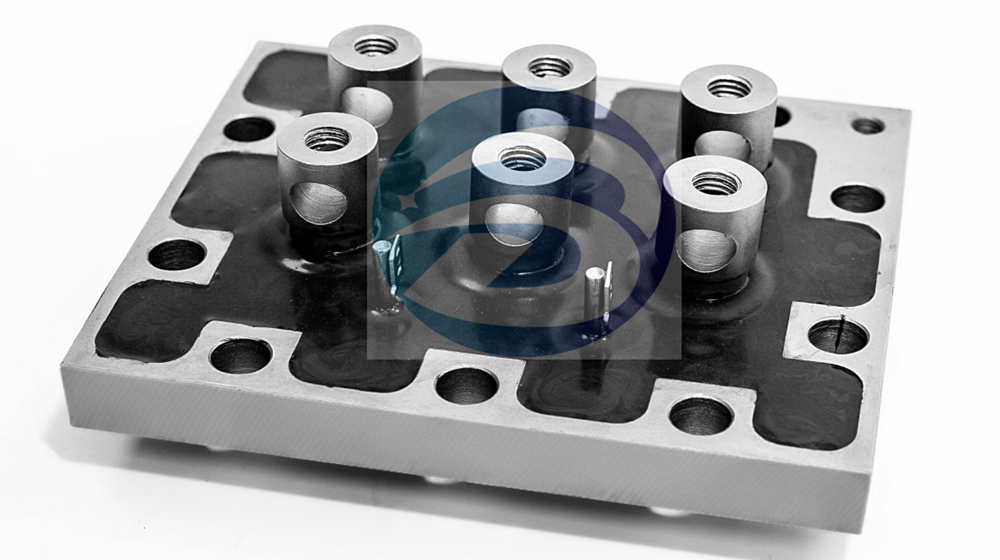

The Bitzer terminal plate is a critical component of the compressor’s electrical system, primarily responsible for electrical connections, signal transmission, and safety isolation. A high-quality terminal plate not only enhances the compressor’s stability and safety but also reduces maintenance costs and extends its service life.

When repairing, refurbishing, or rebuilding a Bitzer compressor, selecting the right terminal plate is essential. If you need a specific model of Bitzer terminal plate, you can provide a drawing or sample, and we can customize production for you!

When selecting a Bitzer compressor terminal plate, it is essential to ensure that it matches the compressor model, electrical parameters, and wiring requirements. Below is a detailed guide on how to choose the right Bitzer terminal plate.

The model number of a Bitzer compressor is typically printed on the nameplate, which includes details such as the series, specifications, and electrical parameters.

Examples include: 4NES-14Y(4-series semi-hermetic piston compressor); CSH7553-90Y(CSH-series screw compressor); Ecoline 6F-50.2Y(Ecoline piston compressor)

When selecting a Bitzer terminal plate, it is crucial to confirm the complete compressor model to ensure that the interfaces, dimensions, and electrical parameters of the terminal plate are compatible.

Before purchasing or replacing a Bitzer terminal plate, it is essential to check the following key parameters.

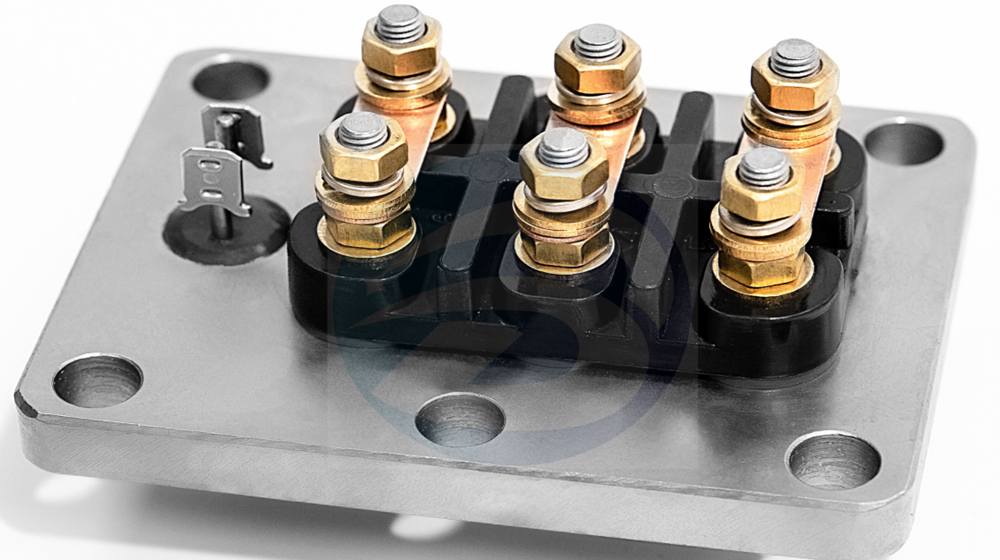

Different Bitzer compressor series may have varying terminal plate structures. It is crucial to select a model that matches the number and layout of the compressor’s terminals.

For example, piston compressorterminal plates are generally smaller, while screw compressor terminal plates may have more terminals.

Check the rated voltageof the terminal plate (e.g., 380V, 460V, 230V) and its maximum current capacity to ensure compatibility with the compressor’s motor specifications.

For instance, if the compressor operates on three-phase 380V power, but theBitzer terminal plate only supports 220V, it will not be compatible.

Star (Y) or Delta (Δ) Connection:The compressor’s wiring method must match the Bitzer terminal plate’s supported wiring configuration.

Single-Speed or Dual-Speed:Some Bitzer compressors support dual-speed operation, requiring a terminal plate that accommodates dual-speed wiring terminals.

If you are unsure about the required terminal plate model, you can:

Provide the compressor model and a photo of the nameplate, and I can help you identify the compatible Bitzer terminal plate.

Contact a Bitzer authorized distributor or technical supportfor official recommendations.

Refer to the Bitzer official parts catalogto select the correct terminal plate.

Common materials used for Bitzer terminal plates include electrical-grade plastic (commonly known as Bakelite), ceramic insulation sheets, ceramic powder and glass powder, as well as steel and copper components. These materials share key advantages such as high-temperature resistance and corrosion resistance.

Bitzer terminal plates are used for the repair, refurbishment, overhauling and remanufacturing of Bitzer compressors. If the original terminal plate is damaged or aged, a reliable compressor repair workshop can inspect, repair, and replace it with a suitable alternative. This helps restore proper electrical connections and ensures reliable operation. For older Bitzer compressors undergoing refurbishment, replacing the terminal plate with a brand-new one is essential to maintain proper electrical connectivity.

When replacing a Bitzer terminal plate, it is crucial to ensure that its specifications, wiring method, and voltage rating match the compressor model to avoid electrical failures or equipment damage.

MEDINO has been a leading manufacturer in refrigeration compressor parts field for 10+ years. With experience in electric terminal plates and oil crankcase heaters producing, we can provide high-quality terminal plates and all compressor parts to improve your compressor performance.

You can get a price of this model or send us any question to get any information you would like to know, we will reply to you soonest.